Everything we do at Curtis Packaging is held to the highest standards of excellence, from hiring

the best employees, to investing in the greatest printing and converting technology.

Kerry Brown, Vice President, Operations

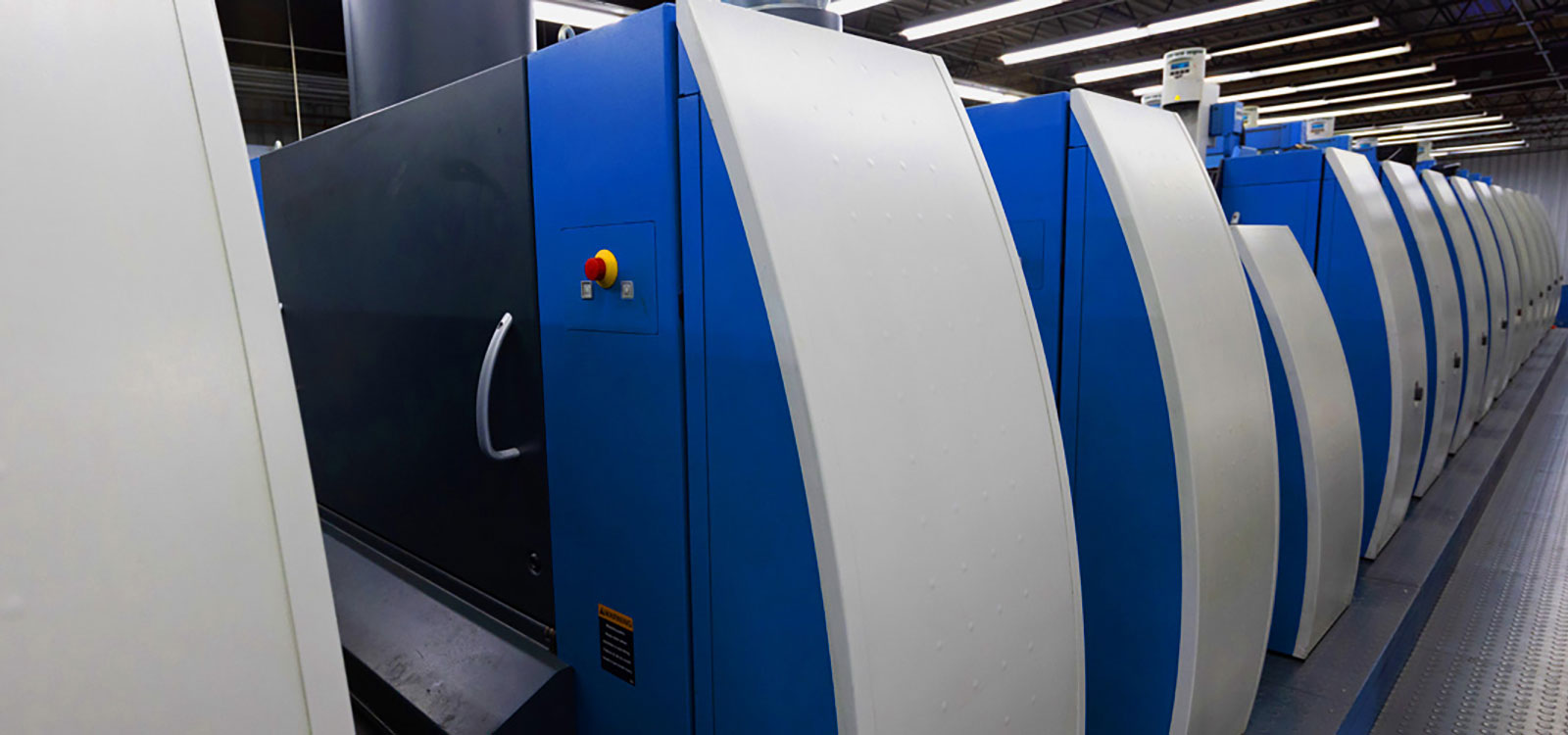

Printing

We have 3 UV Koenig & Bauer presses that afford you the flexibility of printing small runs 20” x 24” sheets to large cartons / high volume runs on our new 42” x 57” press. Our printing equipment is unmatched with unique configurations allowing us to print up to 11 colors complete with multiple coaters.

Ink Lab

We have an on site ink lab for

accurate color matching.

Die Cutting / Die Making

We have proudly made our cutting dies in-house for over 100 years. Our new fleet of Bobst DieCutters ensure precision and efficient throughput.

Hot Stamping

Hot Stamping – nothing exudes luxury more than crisp, clean Hot Stamping. It unabashedly sets itself apart from others on the shelf.

Prep / Pre-Press

We maintain a fully digital workflow. Allowing us to prepare files for the most complex design processes.

SCODIX

State of the art machines are able to add one-of-a-kind finishes. That includes foil, metallic, glitter & more!

We strive to exceed expectations

in every aspect of our business

From design to delivery, we review our processes to improve continuously. We continually meet

our goals by setting challenging targets for quality and production.

These targets require Curtis Packaging to lead the development and implementation

of new technologies and systems so that World Class is not just a description,

but it is also how we operate on a daily basis.

Color IQC Software

This software is utilized to ensure

consistent color quality.

This allows us to:

• Perform detailed spectral analysis

• Continuously compare against color standards

Embossing / Debossing

We take your brand to new heights by embossing / debossing in-line whether blind, multilevel or registered.

ISO Compliance

ISO 9001

ISO 14001

ISO 15378

ISO 50001

ISO 12647-1

ISO 12647-2

Quality Control Lab & Statistical analysis

Our state of the art QC Lab uses advanced technologies to monitor and measure the individual characteristics of each item we produce.

We utilize SQCPack to manage our quality data by implementing real-time SPC charting and statistical analysis in order to monitor and establish capabilities of variables like:

• Color densities • LAB Values

• Score and Bend forces • Ink densities

• Coefficients of friction • Opening forces

Curtis Packaging is a founding member of the Independent Carton Group. The ICG negotiates long term contracts for volume discounts on raw materials. The ICG meets quarterly to discuss industry trends and advancements to assure we are on the forefront of the industry. In addition to providing a mechanism for negotiating, the ICG members act as a contingency plan should a catastrophe arise.